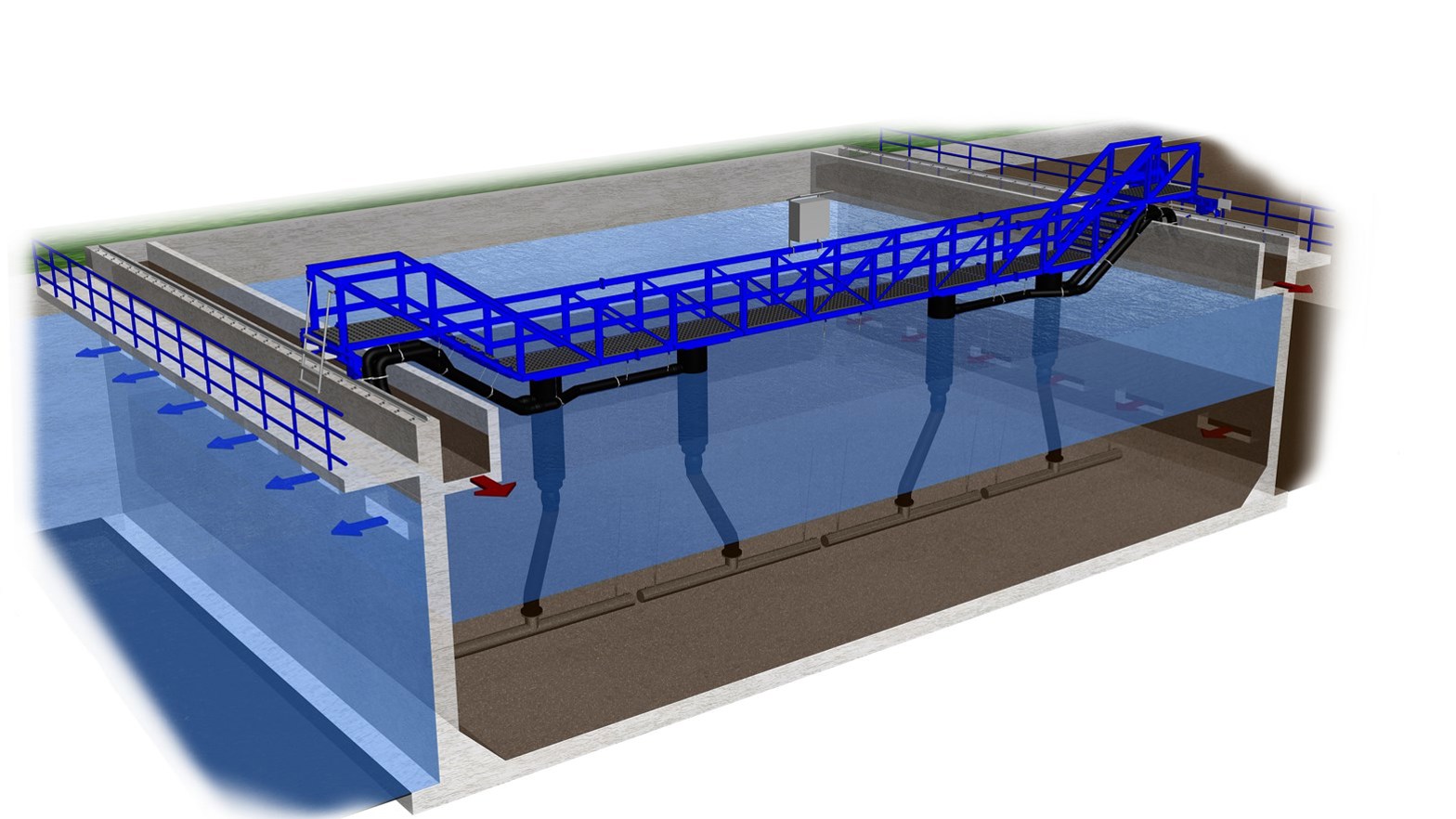

Bioworks® Cross Flow Clarifier

Bioworks Cross Flow Clarifier provides simple and effective solid liquid separation in activated sludge applications while minimizing constructed costs.

Clarifier geometry – it does not necessarily have to be circular

The traditional activated sludge clarifier has a circular shape, with moving scraper bridges and sludge removal system

During high hydraulic loading, for example peak wet weather flow conditions, turbulence in the inlet stilling structure of the clarifier can occur because of increased inlet water velocities. This causes instability and the settling sludge can be stirred up. Some clarifiers are fitted with additional baffles in the entrance structure, or weir deflector baffles to calm down this disturbance and reduce suspended solids carry-over into the launder channel.

The Bioworks® process utilizes a rectangular cross-flow clarifier, which minimizes the hydraulic velocities within the clarification zone, and provides optimum settling conditions for the activated sludge biomass.

This favorable geometry provides excellent solids-liquid separation, to produce a low-solids treated effluent for discharge from the treatment plant.

- The cross-flow clarifier provides the following significant advantages:

- The direct connection of the bioreactor to the clarifier allows more inflow area

- Low inflow velocities of mixed liquor biomass provides minimal sludge blanket disturbance

- Long outlet launder length provides a low hydraulic weir overflow loading rate

- Cost effective construction

- Optimal land utilization through integral design with bioreactor