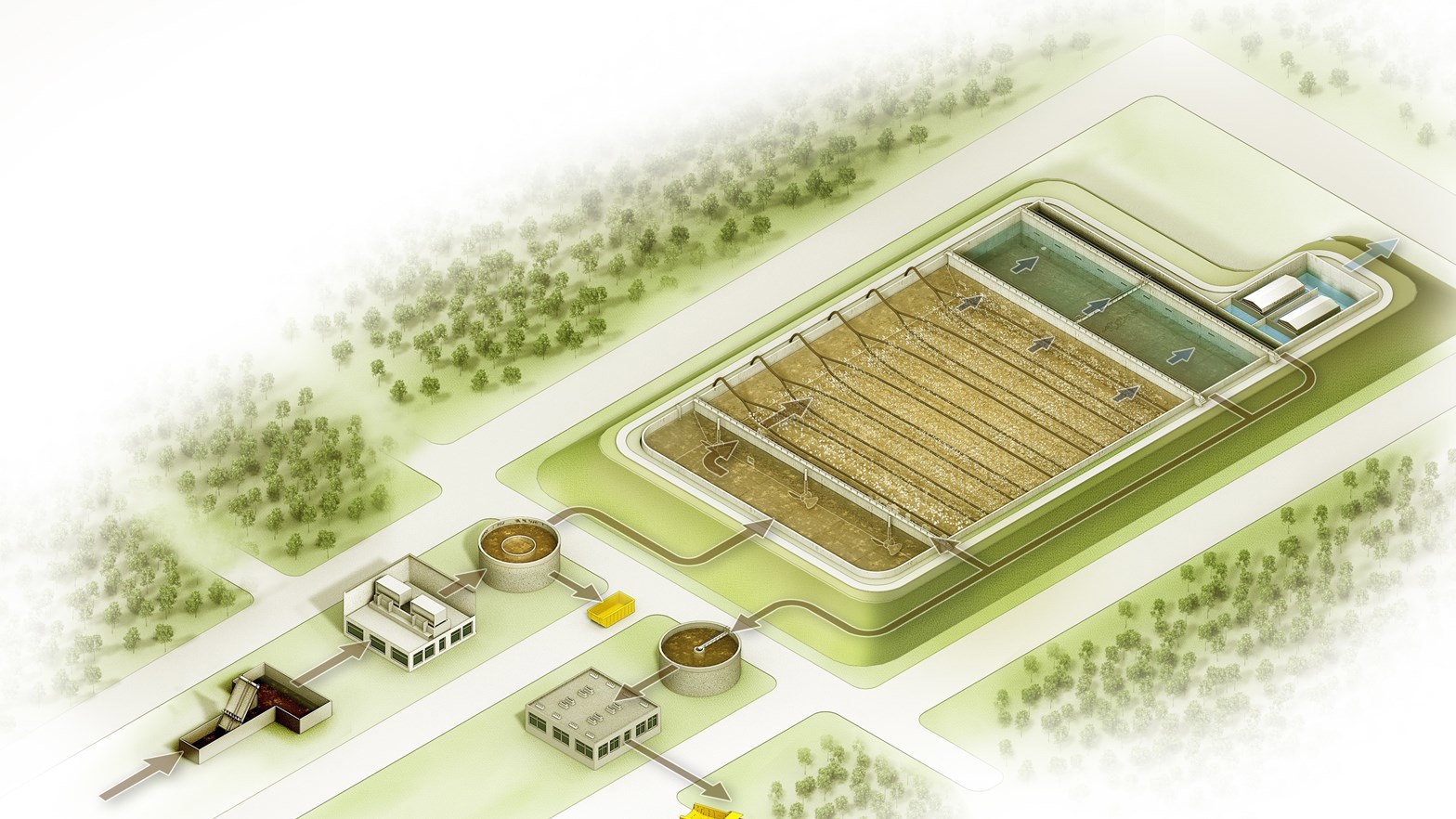

The Bioworks Extended Aeration Treatment Process

The Bioworks long sludge age extended aeration process with fine bubble aeration is an economical and effective solution for wastewater treatment.

How it Works

Bioworks uses a long sludge age in its extended aeration activated sludge treatment process to create wastewater treatment systems that are easy to operate and consistently produce high quality effluent. The long sludge age improves the system’s performance because it makes the biological system less susceptible to peaks, upsets, and unexpected events that can create process problems at the plant.

By combining this biological treatment system with a lagoon style basin and high efficiency fine bubble aeration, Bioworks offers the most cost effective option to maximize your level of treatment.

Inlet works / screening

Bioworks recommends using 3mm bar screens or smaller to reduce biological loading and minimize plant maintenance caused by solids that enter the biological system. We can include a robust, low maintenance fine screen with a high level of separation in our systems if required.

Grit and Grease Removal

For flows with large amounts of grit or grease, Bioworks recommends using grit removal systems and/or grease traps. Grit can accumulate in the system and cause maintenance problems as well as shorten the life of equipment in the plant. Removing grease will reduce the biological loading on the plant and reduce maintenance if a high grease concentration in the influent causes buildup in the system. We can include this in our system if required.

Biological Phosphorus Removal Zone

The biological process starts with the Bio-P zone if phosphorus removal is required, in this selector basin organic acids are created under an anaerobic environment and this enables the growth of phosphorus accumulating bacteria to absorb phosphates in the aerobic basin. Effluent values of total P < 1 mg/l without chemical dosage are possible with biological phosphorus removal. If lower phosphorus concentrations are required, metal salts can be added to reduce phosphorus to lower levels.

Bioworks activated sludge basin

The most important BOD and nitrogen removal process step is conducted in the main Bioworks activated sludge basin. Carbon constituents in the wastewater are reduced and ammonia nitrified by the various kinds of bacteria present in the biomass. The highly efficient suspended Oxiworks fine bubble aeration system ensures oxygen supply to the aerobic zones, enabling the bacteria to work as efficiently as possible, in addition to providing adequate mixing of the bioreactor. Because the floating aeration headers naturally move, mixing is achieved with less energy than other systems.

If required, denitrification is achieved in the bioreactor through alternating aerobic and anoxic zones within the reactor. This is accomplished simply, through timed alternation of air supply to the floating aeration headers, creating phased and alternating aerobic and anoxic zones. In the anoxic zones, where oxygen bound as nitrate, the biomass will oxidize carbon compounds and nitrogen gas will be released to the atmosphere.

Achieving simultaneous nitrification and denitrification within the same process basin, using the highly efficient Oxiworks fine bubble aeration system, results in lower energy usage and minimizes waste sludge production.

Crossflow Clarifier

After treatment in the bioreactor, the activated sludge flows into the clarifier for solids-liquid separation. In the clarifier, the settled biomass is withdrawn from the bottom of the tank, and is recycled to the inlet of the bioreactor to maintain the biomass solids concentrations for the process. Clarified treated effluent passes from the settling zone for discharge, or for further treatment if required. Bioworks also uses other types of clarifiers depending on the requirements of the job.

Tertiary Treatment

If disinfection, or removal of solids below 5 mg/L is required, Bioworks will employ a tertiary treatment system to meet all effluent requirements and ensure the best quality water is released to the environment.